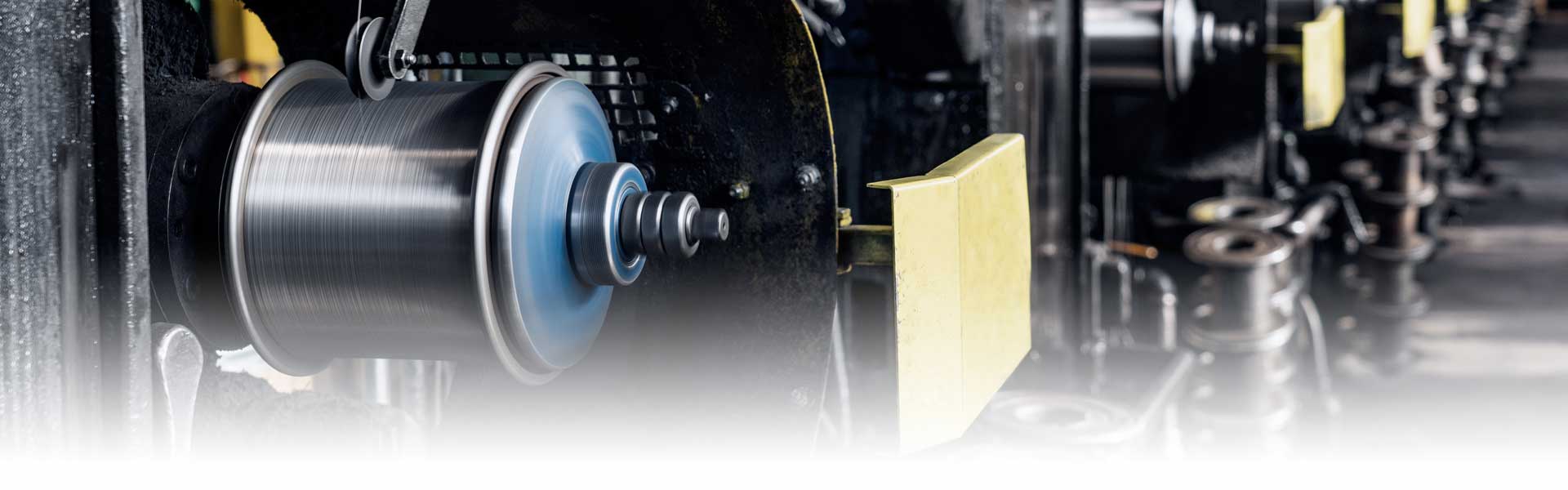

As a manufacturer of fine wire, we offer our own ‘partners in design’ approach to ensure our products are optimized to meet our customers’ production requirements. From certified documentation of our raw materials, consistency and precision in our drawing and heat treatment processes, to providing customized spooling and packaging solutions, IWM ensures the best value to our customers. IWM maintains excellence in our product quality through stringent compliance to our ISO 9001:2015 certified quality management systems.

Below, please find general specifications for several of our single end, round fine wires which are typically in continuous production. For additional information concerning available sizes, material specifications, and technical processes for our wire see our Technical section concerning materials and wire specifications.

We invite you to learn more about IWM capabilities in supporting your fine wire requirements and to see why our customers have continued to rely on our quality products since 1888.

Aluminum Fine Wire

Applications include: Braided Shielding for Electrical & Coaxial Cable, Packaging, Wire Weaving

IWM offers a variety of aluminum alloy fine wire in diameters starting at 0.005in. (36 ga.). IWM aluminum wire is used extensively for braided shielding in electrical and coaxial cable. IWM offers DFARS compliant aluminum wire for US government and military applications. IWM is in continuous production of 0.0126in. diameter 5154 single end, round aluminum wire which is compliant for use as MIL-DTL-24640 shipboard electric cable armor wire.

General Specifications & Capabilities

| Alloys | 5000 Series, Other Alloys Upon Request | Diameter Range: | 0.005in. – 0.064in. |

| Std. Tolerances: | +/-0.0002in. Diameter | Heat Treatments: | To Specification |

| Fleeting Lay Ratio: | 5 Minimum | Std. Packaging: | Aluminum, Fiber, or Plastic

Spool or Bobbin

Delivered Boxed or Racked Tubular Wire Carriers |

| Alloys: | 5000 Series, Other Alloys Upon Request |

| Std. Tolerances: | +/-0.0002in. Diameter |

| Fleeting Lay Ratio: | 5 Minimum |

| Diameter Range: | 0.005in. – 0.064in. |

| Heat Treatments: | To Specification |

| Std. Packaging: | Aluminum, Fiber, or Plastic Spool or Bobbin Delivered Boxed or Racked Tubular Wire Carriers |

Low Carbon Steel Fine Wire

Applications include: Wire Weaving, Packaging, Binding Wire

IWM offers a variety of low carbon steel fine wire, galvanized or copper coated, in diameters starting at 0.005in. (36ga.). IWM steel wire is extensively used for mechanical applications requiring clean, consistent manufacturing processes such as wire weaving, packaging, and binding wire. IWM offers cold heading grade wire for use in the manufacture of fasteners and hardware.

General Specifications & Capabilities

| Alloys | AISI 1005 – 1010 Low Carbon | Diameter Range: | 0.005in. – 0.025in. |

| Std. Tolerances: | +/-0.0002in. Diameter | Heat Treatments: | To Specification |

| Fleeting Lay Ratio: | 5 Minimum | Std. Packaging: | Steel or Plastic Spools with Corrosion Inhibiting Wrap Delivered Boxed or Wrapped Tubular Wire Carriers |

| Alloys: | AISI 1005 – 1010 Low Carbon |

| Std. Tolerances: | +/-0.0002in. Diameter |

| Fleeting Lay Ratio: | 5 Minimum |

| Diameter Range: | 0.005in. – 0.025in. |

| Heat Treatments: | To Specification |

| Std. Packaging: | Steel or Plastic Spools with Corrosion Inhibiting Wrap Delivered Boxed or Wrapped Tubular Wire Carriers |

Copper Alloys & Commercial Bronze Fine Wire

Applications include: Conductive Meshes & Ribbons, Marine Hardware & Connectors, RFI Shielding

IWM offers copper alloys in diameters starting at 0.005in. (36ga.) in diameter. IWM copper wire is used for wire weaving for conductive meshes, conductive ribbons, and RFI shielding applications. IWM is typically in production of Commercial Bronze (Alloy 220) which is used for overbraid shielding and hardware for marine and high corrosive applications.

General Specifications & Capabilities

| Alloys | UNS C100 Copper UNS C200 Brass | Diameter Range: | 0.005in. – 0.025in. |

| Std. Tolerances: | +/-0.0002in. Diameter | Heat Treatments: | To Specification |

| Fleeting Lay Ratio: | 5 Minimum | Std. Packaging: | Steel or Plastic Spools and Bobbins Delivered Boxed or Wrapped Tubular Wire Carriers |

| Alloys: | UNS C100 Copper UNS C200 Brass |

| Std. Tolerances: | +/-0.0002in. Diameter |

| Fleeting Lay Ratio: | 5 Minimum |

| Diameter Range: | 0.005in. – 0.025in. |

| Heat Treatments: | To Specification |

| Std. Packaging: | Steel or Plastic Spools and Bobbins Delivered Boxed or Wrapped Tubular Wire Carriers |